Professional Leaf Blowing Techniques: Master Efficiency & Safety in 2025

Leaf blowing may seem straightforward, but mastering professional leaf blowing techniques transforms a simple task into an art form that balances efficiency, precision, and safety. In 2025, those who elevate their approach through advanced methods and equipment mastery stand out—whether landscapers, property managers, or dedicated homeowners aiming for flawless results.

I. Introduction: Defining “Professional” Leaf Blowing

Professional leaf blowing extends beyond basic clearing. It embodies a disciplined approach that values efficiency, thoroughness, and equipment mastery, while strictly adhering to safety standards. This approach ensures client satisfaction and environmental responsibility—key in modern landscaping.

Beneficiaries of these techniques include commercial landscapers overseeing vast properties, property managers maintaining community spaces, and homeowners committed to exceptional yard care. The goal of this guide is to equip you with actionable insights and expert tips that lead to unparalleled leaf blowing results.

II. Pre-Blowing Preparation: Setting the Stage for Success

A. Site Assessment & Strategy

Successful leaf blowing begins with a detailed analysis of the property layout. Identifying obstacles such as hardscapes (paths, patios) and softscapes (lawns, flower beds) helps plan where leaves should accumulate for easy collection. Understanding wind direction and speed, plus moisture levels—distinguishing between wet and dry leaves—is essential for timing and technique selection.

Dividing the property into manageable work zones facilitates systematic clearing, minimizing missed spots and redundant effort.

B. Equipment Selection & Readiness

Choosing the right type of leaf blower tailors performance to the task:

- Handheld blowers for smaller yards and tight spaces.

- Backpack blowers providing power and comfort for larger areas.

- Walk-behind blowers suited for extensive properties needing heavy-duty clearing.

Optimization extends to nozzle selection—flat nozzles for wide, sweeping air streams; round nozzles for concentrated power; and specialty nozzles designed for intricate tasks.

Managing fuel or battery power correctly is critical. For gas blowers, adhere to proper fuel mix ratios and maintain throttle control to conserve energy and reduce emissions. For battery-powered models, ensure full charges and monitor battery health for uninterrupted operation.

C. Essential Professional Safety Gear (PPE)

Safety is paramount. Professional operators equip themselves with:

- Hearing protection to counteract blower noise levels that often exceed safe decibel thresholds.

- Eye protection to shield against airborne debris and dust.

- Gloves and sturdy footwear to protect hands and feet from sharp objects and provide grip.

- Dust masks for dusty or allergen-prone environments.

This focus on protective gear aligns with guidelines from OSHA and industry best practices.

III. Core Blowing Techniques: Patterns & Posture for Efficiency

A. Establishing Proper Stance & Ergonomics

Ergonomics reduce fatigue and enhance control. Maintain a balanced stance with feet shoulder-width apart, distributing weight evenly. Hold the blower at an optimal angle to direct the air stream efficiently without wasting energy or creating excessive dust clouds.

B. Fundamental Blowing Patterns

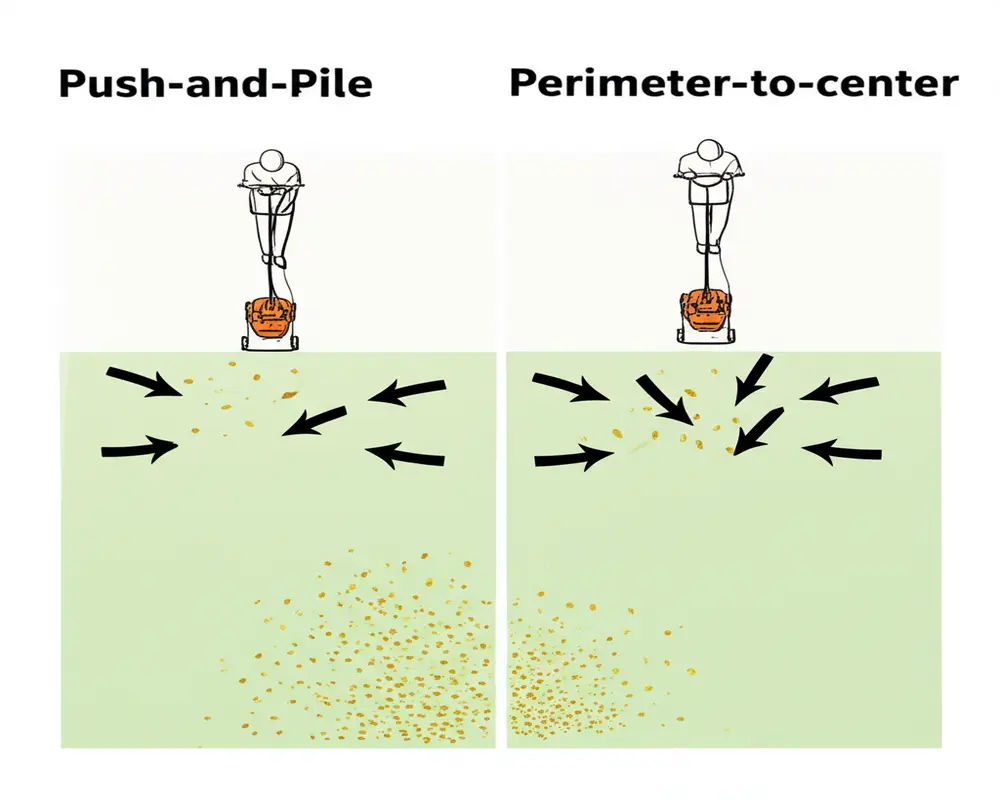

Employing systematic patterns improves thoroughness and speed:

- Push-and-Pile Method: Direct leaves into piles by steadily pushing them along the ground.

- Perimeter-to-Center: Start around the property edges, moving inward to consolidate leaves centrally.

- Grid or Strip Pattern: Divide the area into strips and clear sequentially for uniform coverage.

- Wind-Assisted Blowing: Leverage natural wind direction to aid leaf movement, reducing blower workload.

C. Air Stream Manipulation

Master operators modulate the blower’s air stream to tackle layered leaf accumulations and navigate around obstacles. Applying layered blowing techniques helps lift leaves embedded beneath debris, while adjusting the blower's distance and angle prevents scattering leaves back into cleared zones.

IV. Advanced Techniques & Scenario-Specific Strategies

A. Handling Challenging Leaf Conditions

Wet leaves adhere more stubbornly, requiring a lower air speed and more targeted blowing to avoid clumping or damaging turf. Embedded leaves may need preliminary loosening with rakes or gentle air bursts.

B. Blowing on Different Surfaces

Surface type dictates technique. On lawns, use a gentle, sweeping motion to avoid turf damage. Hard surfaces like driveways and patios tolerate stronger blasts but watch for scattering debris. Flower beds require delicate, controlled blowing to protect plants. Gutters need specialized nozzles or vacuum attachments for effective clearing.

C. Strategic Leaf Staging & Collection

Efficient leaf collection involves creating manageable piles or using tarps to transport leaves swiftly. Collaborating with team members to coordinate blowing and collection optimizes workflow and minimizes time spent.

D. Preventing Re-accumulation

Final perimeter passes and boundary blowing prevent leaves from drifting back into cleared areas. Identifying “hot spots” prone to leaf buildup allows for targeted follow-up maintenance.

V. Equipment Mastery for Performance & Longevity

A. Understanding Blower Capabilities

Knowledge of blower metrics such as cubic feet per minute (CFM), miles per hour (MPH) air speed, and noise levels allows selection of the right tool for specific jobs. Higher CFM and MPH indicate greater leaf-moving power but often come with increased noise.

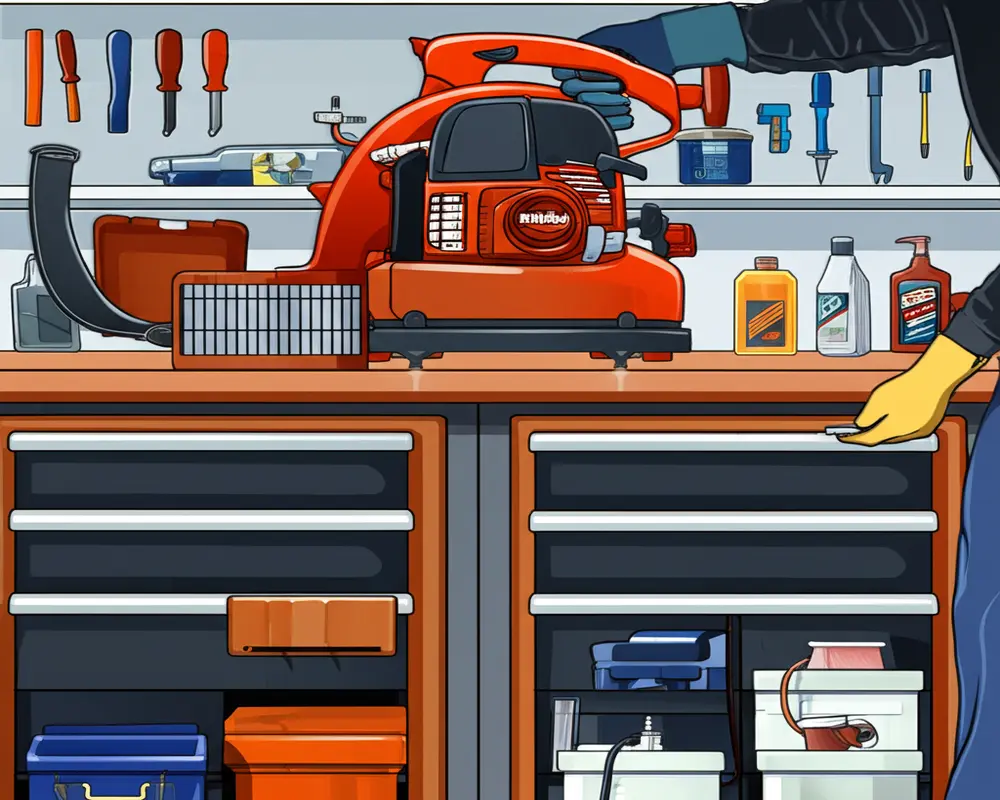

B. Routine Maintenance

Regular upkeep extends equipment life and maintains peak performance. This includes inspecting and cleaning the air filter, checking and replacing the spark plug, maintaining the fuel system, and tightening housing components. Proper maintenance reduces the risk of breakdowns mid-job.

C. Troubleshooting Common Issues

Operators should be prepared to address power loss, starting difficulties, or unusual vibrations. Often, fuel quality, clogged filters, or loose parts are the culprits. Familiarity with these issues accelerates repairs and minimizes downtime.

VI. Professional Best Practices & Business Insights

A. Time Management & Job Estimation

Accurate job time estimation based on property size and leaf volume ensures efficient scheduling and resource allocation. Prioritize tasks and work zones to optimize flow.

B. Client Communication & Expectations

Clear communication about job scope, timing, and environmental considerations builds client trust and satisfaction.

C. Environmental Responsibility

Incorporate sustainable practices such as composting leaves or mulching to reduce waste and support soil health. Refer to EPA’s guidelines on environmental impact to minimize emissions and noise pollution.

D. Legal & Regulatory Compliance

Stay informed of local noise ordinances and debris regulations to avoid fines and maintain community goodwill.

E. Continuous Improvement

Review each job to identify opportunities for technique enhancement and equipment upgrades. Engage with industry research such as from Horticulture Research International and publications like Landscape Management Magazine for ongoing education.

VII. Conclusion: Elevating Your Leaf Blowing Prowess

Mastering professional leaf blowing techniques in 2025 requires a blend of efficiency, precision, safety, and equipment proficiency. Ongoing practice and adaptation to evolving conditions ensure each property achieves a spotless appearance with minimal environmental impact.

Take pride in the satisfaction derived from a perfectly cleared landscape, knowing your skills uphold the highest standards of professionalism and care.

FAQs About Professional Leaf Blowing Techniques

- What safety gear is essential for professional leaf blowing?

- Key safety gear includes hearing protection, eye protection, gloves, sturdy footwear, and dust masks in dusty environments. These protect against noise, debris, and physical hazards.

- How do wet leaves affect leaf blowing?

- Wet leaves require gentler air streams and sometimes preliminary loosening because they stick together and to surfaces, making them harder to move efficiently.

- What maintenance is necessary for leaf blowers?

- Routine maintenance involves cleaning or replacing air filters, checking spark plugs, inspecting fuel lines, and overall equipment inspection to ensure reliable operation.

- Why is understanding blowing patterns important?

- Blowing patterns like push-and-pile or perimeter-to-center optimize leaf movement, reduce missed areas, and speed up the job.

- How can environmental impact be minimized?

- Use electric or battery-powered blowers, avoid blowing leaves onto streets, and consider composting or mulching leaves instead of disposal. Following EPA guidelines is recommended.

For further insights into garden tool maintenance and efficient gardening practices, explore our detailed guides such as the Garden Spade Maintenance and Pruning Shears Comfort Guide.