Leaf Blower Won't Start? Ultimate 2025 Fix & Troubleshooting Guide

It’s frustrating when your leaf blower won't start just as you’re ready to tidy up your yard. Whether it's a stubborn no-crank or a sputtering engine, this guide provides clear, expert-backed steps to diagnose and fix common issues with your leaf blower in 2025. We’ll walk through safety precautions, simple quick checks, and detailed troubleshooting for fuel, ignition, air, and engine systems to get your machine running smoothly again.

Safety First: Essential Precautions Before You Begin

Before you dive into any repair or maintenance, safety is paramount. Always disconnect the spark plug to prevent accidental starting. Work in a well-ventilated area when handling fuel to avoid inhaling fumes. Wear gloves, eye protection, and appropriate personal protective equipment (PPE) to shield against fuel spills and debris. Make sure the engine is cool to the touch to avoid burns. Keep a fire extinguisher handy when working with fuel, as gasoline is highly flammable. Taking these precautions reduces risks as you troubleshoot your leaf blower.

Initial Quick Checks: Simplest Solutions First

A. Check Fuel Level and Type

Start by verifying there is enough fuel in the tank. Many leaf blowers require a specific fuel type: either a 2-stroke fuel mixture (gasoline mixed with oil) or straight gasoline for 4-stroke engines. Using the wrong mixture or stale fuel can prevent your blower from starting. Check the fuel’s freshness, as fuel older than 30 days can degrade and lead to starting problems.

B. Verify Kill Switch Position

Confirm that the kill switch or stop switch is in the ON or RUN position. It's a simple step but often overlooked.

C. Inspect Primer Bulb

The primer bulb injects fuel into the carburetor to prime the engine before starting. Check for cracks, brittleness, or leaks. A damaged primer bulb will not function properly and may need replacement.

D. Check for Exhaust Port or Muffler Blockages

Inspect the exhaust port and muffler for buildup or blockages that can restrict airflow and cause the engine not to start or run poorly.

E. Confirm Choke Engagement

Ensure the choke is correctly set for the engine’s temperature. For cold starts, the choke should be engaged (closed) to enrich the fuel mixture; for warm starts, it should be disengaged (opened).

Step-by-Step Diagnostic and Repair Guide: Core Systems

A. Fuel System Issues (Most Common Causes)

1. Old or Contaminated Fuel

Ethanol in fuel can separate over time, leading to stale or contaminated fuel that clogs your engine. Symptoms include hard starting or failure to start. Fully drain the fuel tank and carburetor, then refill with fresh, stabilized fuel as recommended by the EPA fuel guidelines.

2. Clogged Fuel Filter

A dirty fuel filter restricts fuel flow. Remove and inspect the filter; if it looks clogged or dirty, replace it with a compatible filter.

3. Cracked or Kinked Fuel Lines

Check fuel lines for cracks or kinks that can block fuel delivery. Replace damaged lines with ethanol-resistant fuel lines to ensure durability.

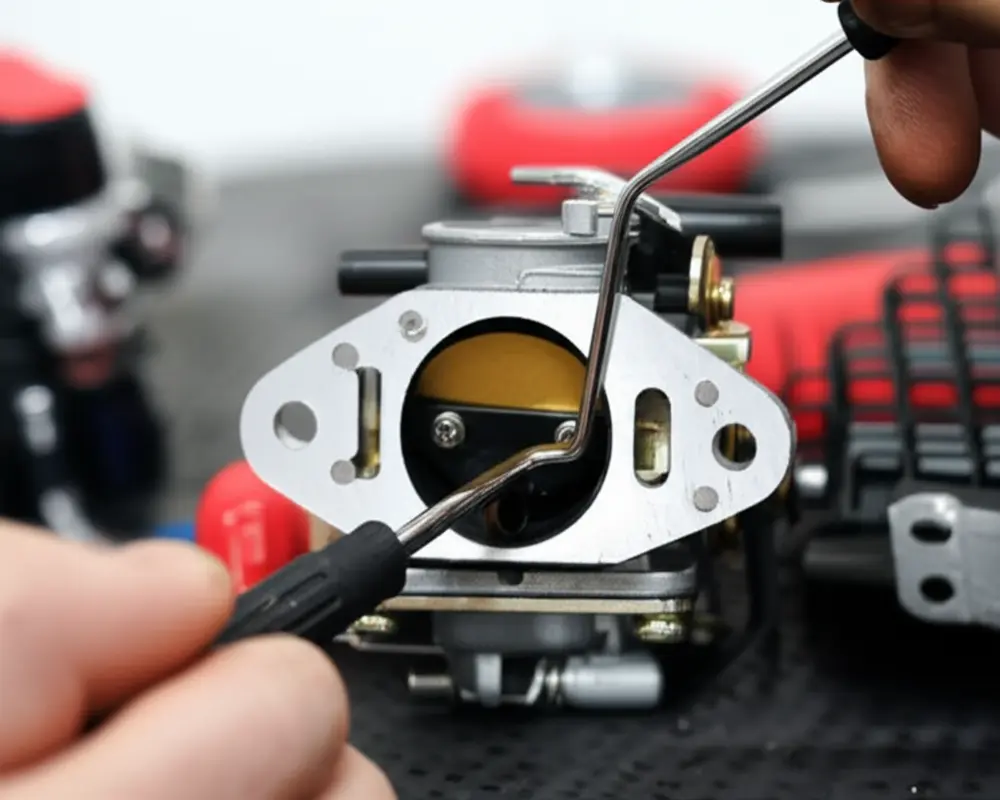

4. Carburetor Problems

Carburetor issues often cause no start or rough running. Symptoms include sputtering, stalling, or failure to start. Cleaning the carburetor thoroughly can resolve many issues:

- Start with an external spray to remove surface dirt.

- Disassemble carefully, noting the position of jets and screws.

- Clean jets and internal parts with carburetor cleaner and compressed air.

- Rebuild or replace the carburetor if cleaning does not restore function.

B. Ignition System Issues

1. Fouled or Worn Spark Plug

The spark plug ignites the fuel-air mixture. Inspect the plug for carbon buildup, wear, or damage. Clean the plug, check the gap with a feeler gauge, or replace it if necessary. Test for spark by grounding the plug against the engine block and pulling the starter cord—be cautious to avoid electric shock.

2. Faulty Ignition Coil

A malfunctioning ignition coil can cause no spark. Symptoms include no spark at the plug despite a good plug and proper wiring. Test the coil with a multimeter and replace if defective.

C. Air & Exhaust System Issues

1. Clogged Air Filter

A dirty air filter restricts airflow, leading to poor engine performance and starting issues. Clean or replace the air filter regularly according to manufacturer recommendations.

2. Blocked Spark Arrestor Screen

The spark arrestor screen prevents sparks from exiting the muffler but can become clogged with carbon deposits. Remove and clean the screen carefully to restore proper exhaust flow.

D. Engine Compression Issues

Low engine compression leads to weak or no starts. Symptoms include excessive smoking, poor power, and hard starting. Use a compression tester to check compression. If compression is low, professional repair or engine replacement may be necessary.

E. Recoil Starter/Pull Cord Problems

If the pull cord is stuck or the recoil spring is broken, the engine won’t crank. Inspect the recoil starter assembly for damage. Repair or replace parts as needed, taking care with spring tension to avoid injury.

Essential Tools and Replacement Parts Checklist

Having the right tools and parts on hand makes troubleshooting easier and more effective. Common tools include:

- Socket set and wrenches for disassembly

- Screwdrivers (flathead and Phillips)

- Feeler gauge for spark plug gap measurement

- Carburetor cleaner and compressed air

- Multimeter for electrical testing

- Replacement spark plugs, fuel filters, fuel lines

- Fresh fuel and fuel stabilizer

Preventative Maintenance to Avoid Future Starting Problems

Maintaining your leaf blower properly extends its life and prevents starting issues. Use fresh fuel mixed with stabilizer, especially if the blower will sit unused for more than 30 days. Drain fuel before long-term storage to avoid gum buildup. Regularly inspect and clean or replace the air filter and spark plug. Keep the engine exterior clean to prevent dirt ingress.

Following these maintenance practices can save you time and money on repairs.

When to Call a Professional or Consider Replacement

Sometimes, despite your best efforts, the blower won’t start. Signs that professional help is needed include:

- Persistent low compression diagnosed by testing

- Severe carburetor or engine damage beyond cleaning or simple repairs

- Electrical system faults that require specialized knowledge

- Repeated starting failures after maintenance

Find a reputable small engine repair specialist through trusted sources like the Small Engine Repair Guide or manufacturer service centers. In some cases, replacing the leaf blower may be more cost-effective, especially if the model is outdated or extensively damaged.

Conclusion: Getting Your Leaf Blower Back in Action

When your leaf blower won't start, systematic troubleshooting—from fuel and ignition checks to air and compression diagnostics—can often restore function without costly repairs. Prioritize safety, use fresh fuel, and maintain your machine regularly to prevent future problems. Armed with the knowledge in this guide, you’re equipped to tackle starting issues confidently and keep your leaf blower running smoothly in 2025 and beyond.

For additional gardening tool maintenance tips, explore our guides on digging spade technique and pruning shears handle comfort.

FAQs About Leaf Blower Starting Issues

Q: Why does my leaf blower start then stall immediately?

A: This is often caused by fuel delivery problems such as a clogged carburetor, dirty fuel filter, or old fuel. Cleaning or replacing these parts typically resolves the issue.

Q: How often should I replace the spark plug on my leaf blower?

A: Spark plugs should be inspected annually and replaced if fouled, damaged, or worn. Regular replacement ensures reliable ignition and easy starting.

Q: Can using the wrong fuel mixture damage my leaf blower engine?

A: Yes, using the incorrect fuel or an improper oil-to-gas ratio can cause engine damage, poor performance, and starting problems. Always follow manufacturer specifications.

Q: Is it safe to clean the carburetor myself?

A: Yes, with proper safety precautions and attention to detail, cleaning the carburetor is a manageable DIY task. Follow step-by-step guides and use appropriate cleaning products.

Q: How can I prevent my leaf blower from not starting during storage?

A: Use fresh fuel with stabilizer, run the engine to circulate fuel, and drain the tank and carburetor before extended storage. Proper storage care minimizes starting issues.