Leaf Blower Carburetor Adjustment: A Complete Guide

Introduction

Adjusting the leaf blower carburetor is essential for maintaining optimal performance, fuel efficiency, and reliable starting. The carburetor controls the air-fuel mixture entering the engine, and any imbalance here can cause starting difficulties, unstable idle, power loss, or excessive fuel consumption. This guide focuses on small gasoline engines commonly found in leaf blowers, covering the prevalent carburetor types—primarily diaphragm and float-type carburetors. We will explore typical screw adjustments and practical, safe tuning methods to help you get your leaf blower running smoothly and efficiently.

Understanding the Carburetor System in Leaf Blowers

Carburetor Basics: Air Intake, Fuel Delivery, and Mixture Control

The carburetor functions by mixing air and fuel in the proper ratio for combustion. Air is drawn into the carburetor and mixed with atomized fuel from the fuel delivery system. This air-fuel mixture can be adjusted to ensure the engine runs efficiently under various conditions, from idle to full throttle. Key adjustments control how much air and fuel enter the engine, directly impacting power and fuel economy.

Common Carburetor Types Used in Leaf Blowers

Leaf blowers typically use diaphragm-type carburetors, such as the popular Walbro carburetor leaf blower models, and occasionally float-type carburetors. Diaphragm carburetors are favored for their compactness and ability to operate in any position, making them ideal for handheld tools. Brands like Walbro and Tillotson manufacture diaphragm carburetors widely used in the industry.

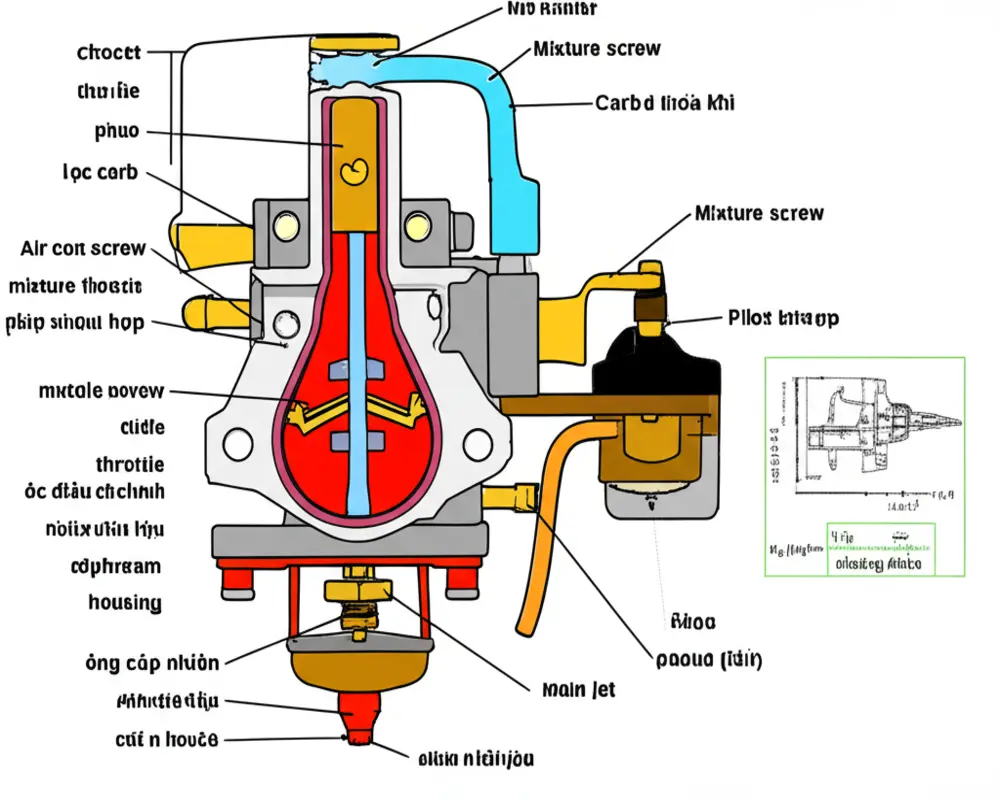

Key Components

The carburetor contains several important parts that influence its operation:

- Idle speed screw: Controls the throttle opening at idle.

- Low-speed and high-speed mixture screws: Adjust the air-fuel mixture at different engine speeds.

- Jets and needle valves: Regulate fuel flow.

- Float bowl: Maintains a consistent fuel level in float-type carburetors.

- Choke: Enriches the mixture for cold starts.

- Primer bulb: Helps prime the carburetor with fuel for easier starting.

- Air filter: Filters incoming air to prevent debris from entering the engine.

Tools, Safety, and Preparation

Personal Protective Equipment

Before beginning any adjustment, ensure you have appropriate safety gear: gloves to protect your hands, eye protection against debris or fuel splashes, and hearing protection to guard against noise from the running engine.

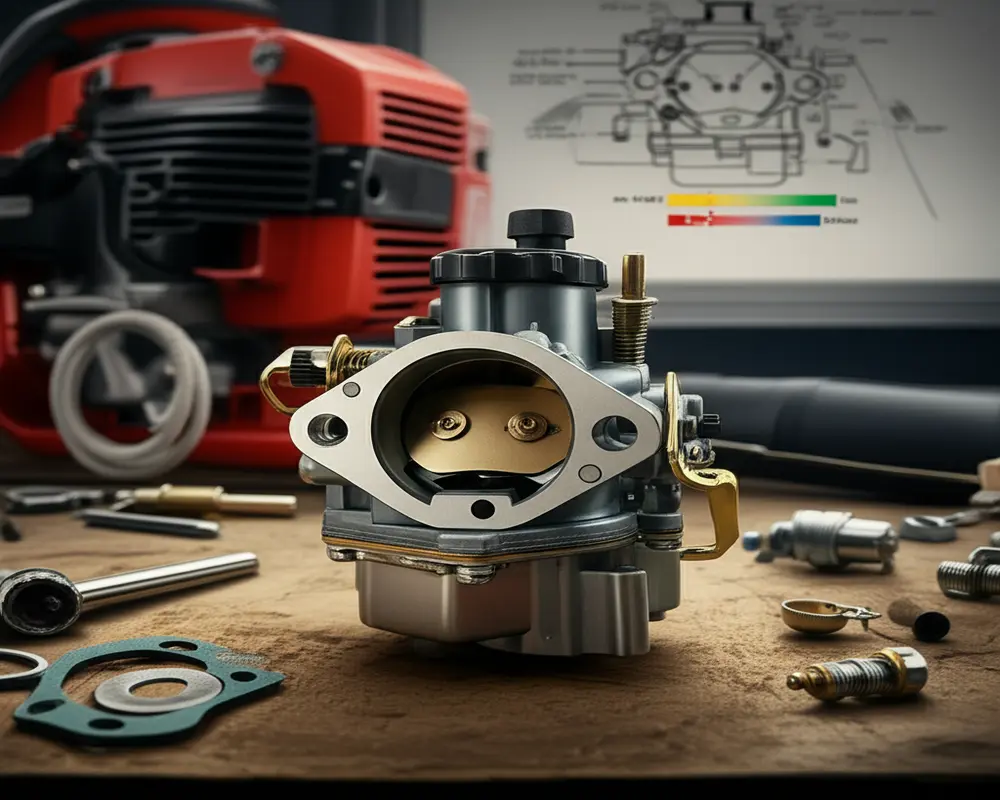

Tools Checklist

For effective carburetor tuning, prepare a set of tools including flat and Phillips screwdrivers, small wrenches, and optionally a tachometer and timing light for precise measurements. Compressed air and clean rags are useful for cleaning, alongside carburetor cleaner to remove deposits.

Workspace and Safety Precautions

Work in a well-ventilated area to avoid inhaling fuel vapors. If necessary, drain the fuel tank to prevent spills. Always ground the spark plug to eliminate the risk of accidental ignition during adjustments.

Symptoms Indicating a Carburetor Adjustment Is Needed

Hard Starting or No-Start Conditions

If your leaf blower struggles to start or fails to start at all, the carburetor’s air-fuel mixture may be too lean or too rich, or the choke may not be functioning properly.

Rough Idle or Stalling at Low Speed

An unstable or rough idle often signals that the carburetor screws controlling the low-speed mixture or idle speed need tuning.

Black Smoke or Rich Smell Indicating Too Much Fuel

Excessive fuel in the mixture causes black smoke and a strong fuel odor, suggesting the carburetor is running rich and requires adjustment.

Lean Running with High Idle, Backfiring, or Overheating

A lean mixture, where there is too much air and insufficient fuel, can cause high idle speeds, backfiring, and engine overheating.

Power Loss at Full Throttle

Loss of power when the throttle is fully open often means the high-speed mixture screw or jetting needs attention.

Step-by-Step Procedure for Adjusting the Carburetor (Baseline)

Safety and Warm-Up

Before tuning, ensure the engine is cool to avoid burns. Disconnect the spark plug boot to prevent accidental starting. Start the engine and allow it to reach normal operating temperature to stabilize the carburetor’s performance.

Baseline Checks and Baseline Settings

Inspect and clean the air filter to ensure unrestricted airflow. Check fuel lines and the fuel filter for blockages or leaks, and verify there are no air leaks around the carburetor mounting. Consult your leaf blower’s manual for the recommended baseline idle speed setting.

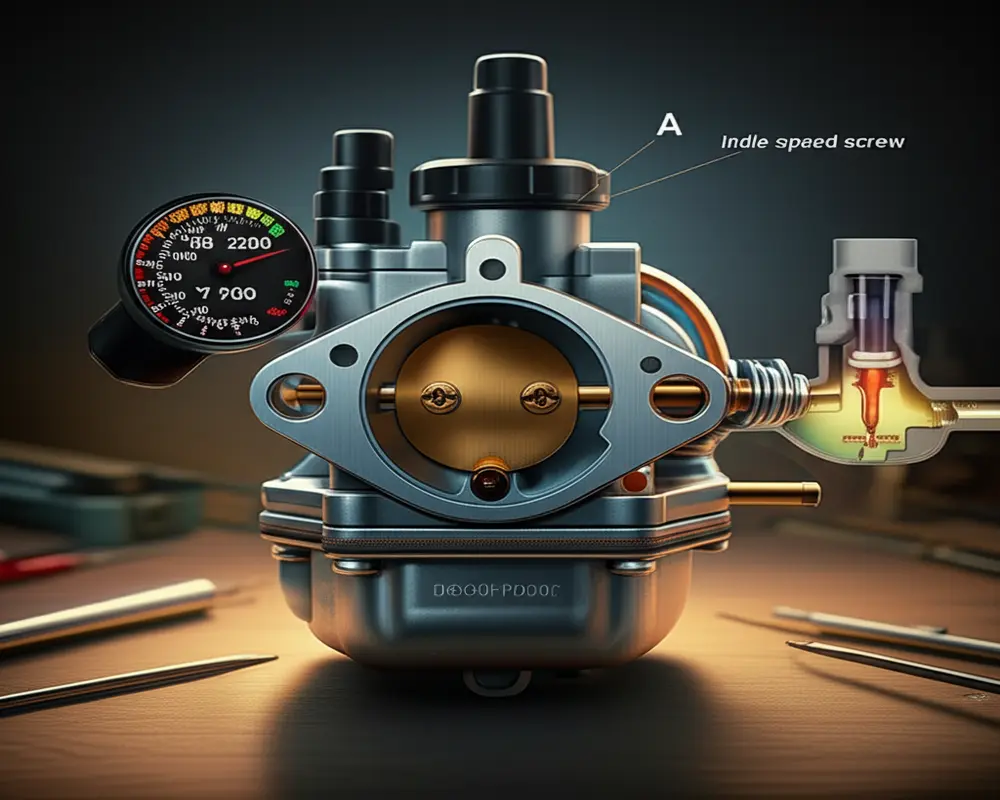

Idle Speed Adjustment

Locate the idle speed screw, usually marked or found near the throttle linkage. Adjust it to reach the recommended RPM (typically around 2,800 to 3,000 RPM for many models). Confirm the engine maintains a steady idle without stalling.

Low-Speed Mixture Adjustment

Adjust the low-speed mixture screws slowly, turning them in or out in small increments. Listen for the smoothest idle and best throttle response at low speeds. Avoid over-adjusting, which can cause irregular idle or stalling.

High-Speed/Air-Fuel Mixture Adjustment

Access the high-speed mixture screw, often located on the side of the carburetor. Adjust it while running the engine under light load, aiming for the highest stable RPM without the engine running too rich (black smoke) or too lean (overheating).

Jet/Needle and Float Adjustments (If Applicable)

Inspect jets for blockages and replace gaskets if leaking. Adjust float height according to the manufacturer’s specifications to maintain proper fuel levels and prevent flooding. Ensure all seals are intact to avoid air leaks.

Choke Position and Cold-Start Enrichers

Verify choke operation to ensure it fully enriches the mixture during cold starts. Adjust the choke linkage or enrichers as needed to promote smooth starting without flooding.

Recheck Idle and Throttle Response After Adjustments

After all adjustments, recheck idle speed and throttle response. The engine should start easily, idle smoothly, and accelerate without hesitation.

Tuning for Different Fuels and Operating Environments

Ethanol Content and Fuel Stability Considerations

Fuels with ethanol blends can cause carburetor gumming and require more frequent tuning. Ethanol also affects fuel volatility, necessitating mixture adjustments for optimal combustion.

Altitude Adjustments for Air Density

Higher altitudes have thinner air, requiring a leaner fuel mixture. Adjust the high-speed and low-speed screws accordingly to compensate for reduced air density and maintain engine performance.

Temperature and Humidity Effects on Air Density and Carb Mixture

Cold, dense air requires richer mixtures, while hot and humid conditions call for leaner mixtures. Fine-tune your carburetor based on local weather conditions for consistent performance.

Cold Weather Starting Adjustments

In cold climates, enrich the mixture by adjusting the choke or idle mixture to facilitate easier starts and prevent stalling.

Maintenance and Long-Term Care

Regular Cleaning and Inspection Schedule

Keep the carburetor clean by periodically removing deposits with carburetor cleaner and inspecting all components for wear or damage.

Replacing Worn Diaphragms, Gaskets, and Seals

Diaphragms and gaskets deteriorate over time, causing leaks or poor fuel delivery. Replace these parts as needed to maintain proper carburetor function.

Fuel System Hygiene and Ethanol-Blend Considerations

Use fresh fuel and additives to stabilize ethanol-blended fuels. Drain fuel before storage to prevent varnish formation inside the carburetor.

Storage Tips for Off-Season Use

Before storing your leaf blower, run fuel stabilizer through the carburetor, clean the air filter, and store the tool in a dry, temperature-controlled environment.

Troubleshooting Quick Fixes

Common issues such as hard starting can often be resolved by priming the carburetor or adjusting the idle screw. If persistent problems occur, consider replacing worn parts or rebuilding the carburetor.

Advanced Adjustments for Performance and Efficiency

For users looking to optimize performance, fine-tuning jet sizes and making micro-adjustments can yield improved fuel economy and power balance. Compatibility with different fuel mixtures, including synthetic oils, should be considered during advanced tuning.

Common Mistakes to Avoid

Avoid over-tightening screws, which can damage gaskets and cause leaks. Never ignore air leaks or dirty air filters, as both will adversely affect carburetor tuning. Always warm up the engine before making any adjustments to ensure accurate settings.

Quick-Reference Cheat Sheet

- Pre-tuning: Safety gear, tools, and workspace setup

- Baseline: Clean air filter, check fuel lines, initial idle speed

- Idle Adjustment: Set RPM to 2,800-3,000

- Low-Speed Mixture: Adjust for smooth idle and throttle response

- High-Speed Mixture: Tune for max RPM without rich/lean extremes

- Post-Tuning: Confirm stable idle and responsive throttle

Internal Linking and Knowledge Integration (SEO)

For more on maintaining your leaf blower’s fuel system and engine health, see our detailed guide on fuel system maintenance. Also, explore tips on engine diagnostics and air filter care to keep your equipment running at peak efficiency.

FAQs

How often should I adjust the carburetor on a leaf blower?

Adjustments should be made when you notice symptoms like hard starting, rough idle, or power loss. Regular inspection every season or after 20-30 hours of use can prevent issues.

Can a dirty air filter affect carburetor adjustment?

Yes, a clogged air filter restricts airflow, causing the engine to run rich. Always clean or replace the air filter before adjusting the carburetor.

What is the correct idle speed for most leaf blowers?

Idle speed typically ranges between 2,800 and 3,000 RPM, but consult your model’s manual for exact specifications.

How do ethanol-blended fuels affect carburetor tuning?

Ethanol can cause fuel system deposits and affect mixture stability, requiring more frequent adjustments and use of fuel stabilizers.

Conclusion

Proper leaf blower carburetor adjustment is vital for smooth starting, efficient fuel use, and reliable performance. By understanding your carburetor’s components, symptoms of misadjustment, and following safe, step-by-step tuning procedures, you can extend your leaf blower’s lifespan and enhance its operation. Regular maintenance and attention to environmental factors will keep your equipment ready for any yard work.