How to Diagnose & Fix Lawn Mower Vibration Problems: A Complete Troubleshooting Guide

Is Your Lawn Mower Shaking Excessively? Don’t Ignore It!

Thank you for reading this post, don't forget to subscribe!Excessive vibration in your lawn mower is more than just a nuisance—it signals underlying lawn mower vibration problems that can compromise safety, reduce cutting quality, and shorten your mower’s lifespan. Ignoring these symptoms may lead to costly repairs or even accidents. This comprehensive 2025 guide offers a methodical approach to diagnosing and resolving these issues, focusing on common causes such as blade imbalance, engine troubles, and deck maintenance. Whether you’re a seasoned DIYer or a cautious beginner, this guide will help you restore smooth operation and extend your mower’s service life.

Section 1: Critical Safety First – Before You Touch Anything!

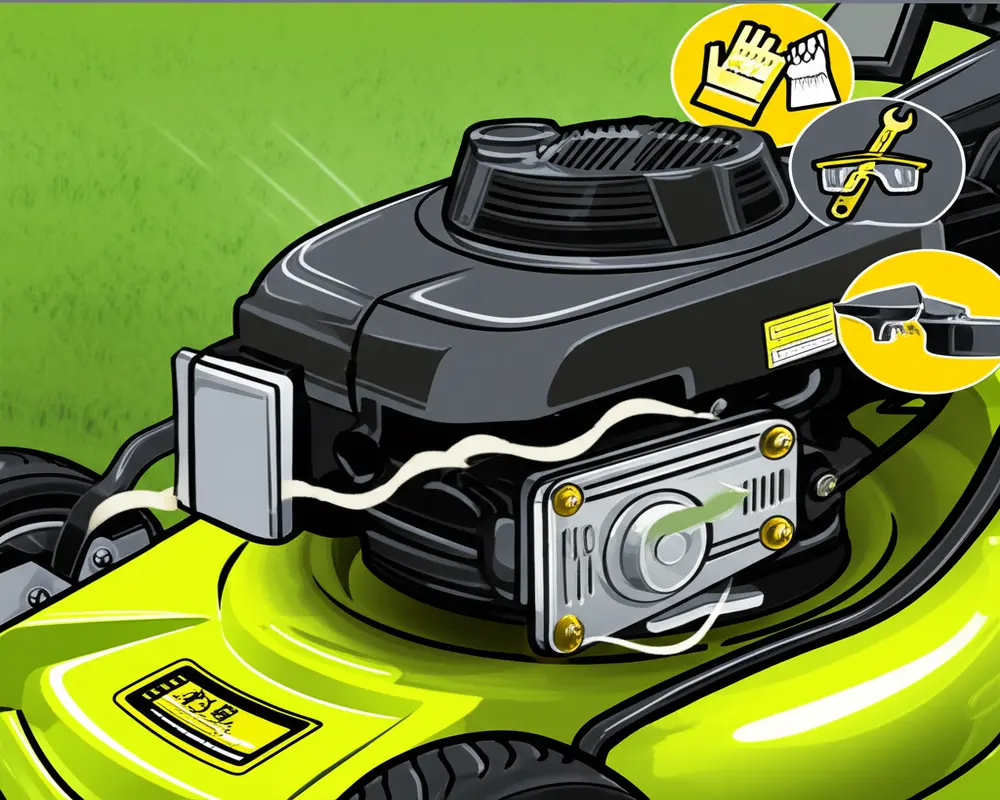

Before attempting any repair or inspection, prioritize safety to protect yourself and your equipment. Always disconnect the spark plug or battery to prevent accidental engine starts. Allow the engine to cool completely before working on it to avoid burns.

Wear protective gear such as gloves and safety glasses, and ensure the mower is stable on a flat surface to prevent tipping. Never attempt maintenance while the engine is running or the blade is spinning. These precautions establish a safe working environment and reduce injury risk.

Section 2: Understanding Your Vibration: What Does It Feel Like?

Pinpointing the nature of the vibration helps to isolate the cause. Vibration can be categorized into types:

- Mild Constant Vibration: Often linked to minor blade imbalance or loose components.

- Sudden Violent Shaking: May indicate bent blades or engine issues.

- Vibration Only When Moving: Often caused by worn wheel bearings or loose wheels.

- Vibration with Noise: Suggests damaged engine or drive parts.

Observing when and how vibration occurs provides vital clues for effective troubleshooting.

Section 3: Essential Tools for DIY Lawn Mower Repair

Equipping yourself with the right tools ensures efficient and safe repair. Common tools include wrenches, socket sets, screwdrivers, and a blade balancer for precise blade adjustments. Wire brushes help clean components, while safety glasses protect your eyes during debris removal. Having these essentials ready sets you up for success in addressing vibration problems.

Section 4: Systematic Troubleshooting Guide – From Simple to Complex

A. The Blade & Cutting Deck

1. Loose or Unsecured Blade

A loose blade causes uneven cutting and noticeable vibration. Symptoms include a wobbling blade and rattling sounds during operation. To diagnose, stop the mower, disconnect power, and check the blade bolt’s tightness. Use a torque wrench to tighten to the manufacturer’s specifications, typically between 30-60 ft-lbs (40-80 Nm). Over-tightening can damage the blade or bolt, so follow torque guidelines carefully.

2. Unbalanced Blade

An unbalanced blade spins unevenly, generating vibration that worsens at higher speeds. Cleaning accumulated grass and dirt from the blade is essential before balancing. Use a blade balancer tool to check balance; remove material from the heavier side to achieve equilibrium. For detailed sharpening techniques, refer to our blade sharpening guide to optimize performance.

3. Bent or Damaged Blade

Blades struck by rocks or roots may bend or crack, causing severe vibration and unsafe operation. Inspect blades visually for deformities or cracks. Bent blades should be replaced promptly to avoid engine damage or injury. Replacement blades should match the model specifications to maintain proper balance and cutting efficiency.

4. Excessive Grass Buildup

Grass and debris accumulation under the cutting deck can unbalance the mower and increase vibration. Symptoms include uneven vibration and reduced cutting quality. Clean the deck regularly using a brush or scraper, especially after mowing wet grass. Prevent buildup by mowing at the correct height and frequency.

B. The Engine & Drive Components

1. Bent Crankshaft

A bent crankshaft is a serious issue causing violent vibration and impaired engine function. Symptoms include rough running, knocking sounds, and excessive vibration at all speeds. Diagnosing requires engine disassembly and specialized tools; this repair is typically beyond most DIY capabilities. If suspected, consult a professional mechanic to assess repair or replacement options.

2. Loose Engine Mount Bolts

Loose or damaged engine mounts allow the engine to vibrate excessively against the frame. Symptoms include noticeable shaking localized around the engine area. Visual inspection can reveal loose bolts or worn mount bushings. Tighten bolts to recommended torque or replace mounts if damaged.

3. Damaged Flywheel

The flywheel’s balance is critical to smooth engine operation. Damage or cracks can cause severe vibration and engine performance issues. Inspect the flywheel during service intervals, looking for cracks, missing fins, or damage. Replacement and flywheel balancing require professional tools and expertise to ensure proper engine timing and balance.

4. Worn Engine Bearings/Internal Issues

Worn bearings or internal engine components cause vibration, noise, and decreased engine life. Symptoms include grinding sounds and inconsistent engine speed. Diagnosing internal issues often involves engine teardown and measurement. Repairs may require professional service or engine replacement depending on severity.

C. Other Contributing Factors

1. Worn Wheel Bearings or Loose Wheels

Wheel issues can transmit vibration to the entire mower, especially when moving. Symptoms include wobbling wheels, uneven movement, or vibration only during mowing. Inspect wheel bearings for wear and replace if necessary. Tighten loose wheel nuts and check for damaged wheel assemblies.

2. Worn Spindle Bearings

Spindle bearings support the blade shaft and affect cutting smoothness. Worn bearings cause vibration and noise during operation. Check spindle play by manually moving the blade spindle; excessive movement indicates bearing wear. Replace spindle bearings to restore smooth operation.

Section 5: When to Call a Professional Lawn Mower Mechanic

While many vibration issues can be addressed by experienced DIYers, some problems require professional expertise. Severe engine internal damage, bent crankshafts, or flywheel issues demand specialized tools and knowledge. Additionally, if you lack the necessary equipment or confidence, consulting a professional ensures safety and cost-effectiveness. Professionals can also perform detailed diagnostics and repairs to restore your mower to optimal condition.

Section 6: Preventing Future Lawn Mower Vibrations

Regular maintenance is the cornerstone of vibration prevention. Maintain a schedule of blade sharpening and balancing every 20-25 hours of mowing or at least annually. Clean the deck after each use to prevent grass buildup. Operate the mower carefully to avoid striking obstacles that can bend blades or damage components. Follow the manufacturer’s maintenance guidelines diligently and store the mower in a dry, protected area to prevent corrosion and wear.

Section 7: Frequently Asked Questions (FAQs)

Can I use the mower with slight vibration?

While minor vibration may be tolerable temporarily, it’s advisable to address it promptly. Continued use with vibration can cause component damage and safety risks.

How often should I balance the blades?

Balancing blades every 20-25 hours of use or at least once a mowing season helps maintain smooth operation and cutting quality.

Can a bent crankshaft be repaired?

Bent crankshafts usually require replacement, as repairs are complex and often unreliable. Consult a professional for assessment.

What causes vibration at certain engine speeds?

This often results from unbalanced rotating parts, engine mount issues, or resonant frequencies in the mower’s design. Proper balancing and mount inspection reduce these vibrations.

Conclusion: Get Your Smooth Mow Back!

Addressing lawn mower vibration problems quickly preserves safety, enhances mower performance, and extends equipment life. By following this guide’s systematic approach—from safety precautions to detailed troubleshooting and preventive maintenance—you can enjoy a smoother, more efficient mowing experience. Remember to consult professionals when severe issues arise, ensuring expert care and peace of mind.

For further detailed insights on lawn mower starting issues and maintenance, visit our guide on lawn mower won’t start.

Authoritative sources for additional information include Briggs & Stratton, Popular Mechanics, and The Home Depot.