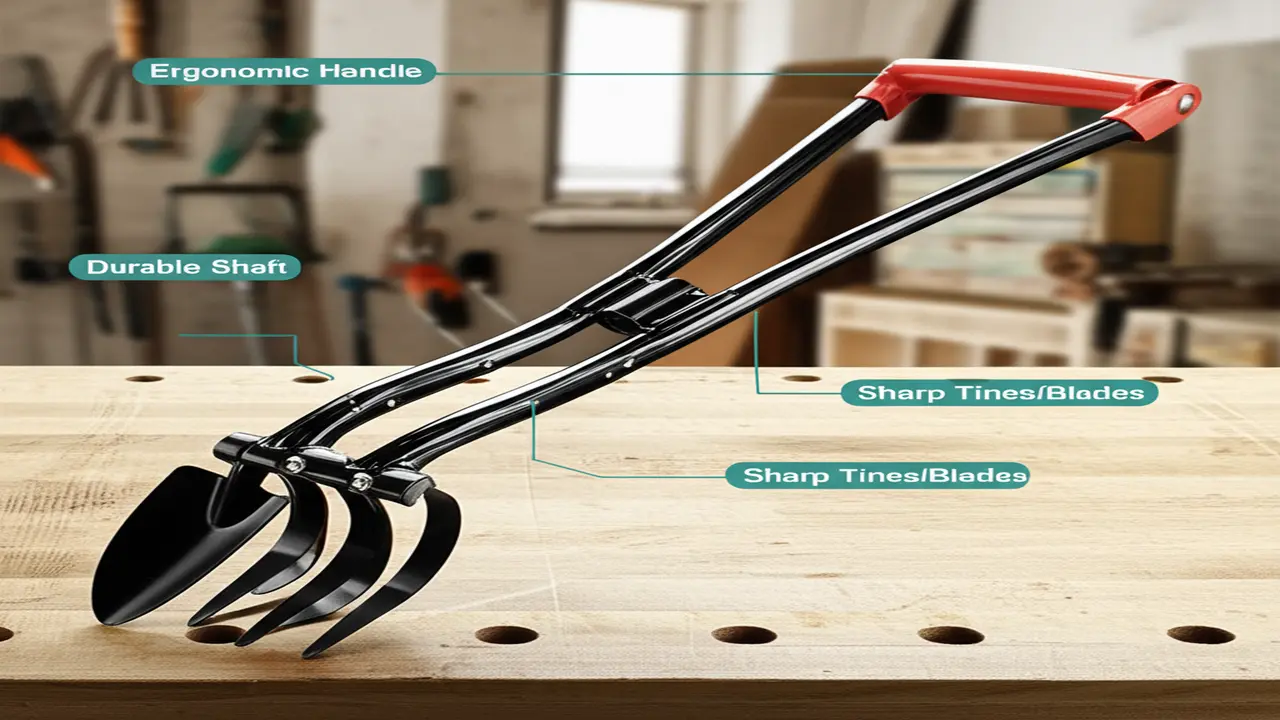

1. Understanding Your Hand Cultivator: Anatomy and Function

* Handle: This is your point of contact, providing grip and leverage. Handles are usually made of wood, plastic, or ergonomic rubber, and a wobbly or cracked handle is a common issue.

* Shaft: The shaft connects the handle to the tines. Its material, often steel or aluminum, determines the tool’s overall rigidity and resistance to bending under pressure.

* Tines: These are the sharp prongs that engage the soil. Their shape, number, and material (usually carbon or stainless steel) dictate how well the tool aerates and breaks up compacted earth.

* Connection Points: Pay close attention to the ferrule (where the shaft meets the handle) and the tang (where the tines are welded to the shaft). These joints are frequent points of failure.

2. Diagnosing and Fixing Common Hand Cultivator Problems

* Bent or Deformed Tines: Striking a hidden rock or a thick root can easily bend a cultivator’s tines, making it dig unevenly and inefficiently. To fix this, secure the tool in a vise or hold it firmly against a solid surface. Use a pair of strong pliers or an adjustable wrench to carefully bend the tine back into its original alignment. Work slowly to avoid overcorrecting or weakening the metal. Always wear gloves to protect your hands during this process.

* Rust on Tines and Metal Parts: Leaving a cultivator exposed to moisture is the primary cause of rust, which can corrode and weaken the metal over time. For light rust, a stiff wire brush or a piece of sandpaper will work. For more stubborn spots, a chemical rust remover may be needed. After removing the rust, it is crucial to clean the tool, dry it completely, and apply a thin coat of protective oil. For more tips on keeping your tool in prime condition, see our guide on hand cultivator maintenance.

* Loose or Wobbly Handle: A loose handle is not just annoying. it’s a safety hazard that reduces your control and leverage. First, check for any loose screws or bolts and tighten them. If the handle is wooden and has shrunk, you might need to insert a small wooden or metal shim into the gap to create a tight fit. Applying a strong wood glue can also solve the problem. If the handle is cracked or the connection point is damaged, replacement is the safest option.

* Dull Tines: Tines will naturally dull with use, forcing you to exert more effort to break up soil. Sharpening them is simple. Secure the cultivator and use a flat metal file or a sharpening stone. Follow the original bevel of the tine’s edge, pushing the file in one direction away from your body. A few firm strokes on each edge should be enough to restore its sharpness for easier soil penetration.

* Difficulty Penetrating Soil: If your cultivator seems to bounce off the ground, the cause is often a combination of the issues above. First, ensure the tines are sharp and straight. If they are, the problem might be the soil itself. Compacted, dry clay can be too tough for a standard cultivator. Try watering the area a day before you plan to work to soften the ground. If the soil is consistently hard, your current tool might not be robust enough for the task.

3. Proactive Maintenance for Longevity and Performance

Here are the core preventative measures for 2025:

* Cleaning and Drying: Always remove caked-on soil and moisture after each use. A stiff brush and a dry rag are your best friends here. This single step is the most effective way to prevent rust from forming on the tines and tang.

* Oiling Metal Parts: Apply a light coat of lubricating oil, such as 3-in-1 or even simple mineral oil, to all metal surfaces. This creates a protective barrier against humidity.

* Sharpening Tines: Periodically check the sharpness of the tines. A few passes with a mill file will restore the edges, allowing them to slice through soil and roots with less effort.

* Handle Care: For wooden handles, an annual wipe-down with linseed oil prevents cracking and splintering. For plastic or composite handles, simply ensure they are clean and stored away from direct sunlight to prevent degradation.