Maximizing the effectiveness of your pesticide investment is a top priority for any serious gardener or farmer in 2025. Simply spraying is not enough. The secret often lies in using the correct adjuvants for pesticides, which can dramatically improve performance by enhancing spreading, penetration, and sticking properties. From surfactants to oils, the market is vast, and making the wrong choice can waste both product and money. This guide cuts through the noise, providing clear, expert analysis to help you select the most effective adjuvants for your specific application and needs.

1. Defining Adjuvants in Pesticide Applications

In the context of plant protection for 2025, an adjuvant is a substance added to a pesticide formulation or tank mix to enhance the active ingredient’s effectiveness or improve the mixture’s physical properties. It is not a pesticide itself but a performance enhancer. For instance, many plant leaves have a waxy surface that causes water-based sprays to bead up and roll off, wasting the product. Adding a surfactant, a common type of adjuvant, reduces the water’s surface tension, allowing the spray to spread evenly across the leaf for better coverage and absorption. Other adjuvants for pesticides can include oils to improve penetration through the leaf cuticle, stickers to help the chemical adhere to the plant during rain, or drift control agents to minimize off-target application. Essentially, using the correct adjuvant ensures you get the maximum value and impact from your pesticide investment.

2. The Purpose and Functions of Adjuvants

In 2025, think of adjuvants for pesticides not as the main actors, but as essential support crew that ensures the star performer, the pesticide, works effectively. Their primary goal is to enhance the physical and chemical properties of a spray solution, overcoming application challenges to maximize impact. For instance, surfactants, a common type of adjuvant, reduce the surface tension of water. This action allows droplets to spread out across a waxy leaf surface rather than beading up and rolling off, a function known as spreading. Other adjuvants act as stickers, using a glue-like action to help the pesticide adhere to the plant, preventing it from being washed away by rain or irrigation. Meanwhile, emulsifiers are critical for creating a stable mixture when blending incompatible products, such as an oil based pesticide with water. Using the right adjuvant ensures your pesticide application is efficient, cost effective, and successful.

3. Categorizing and Identifying Adjuvant Types

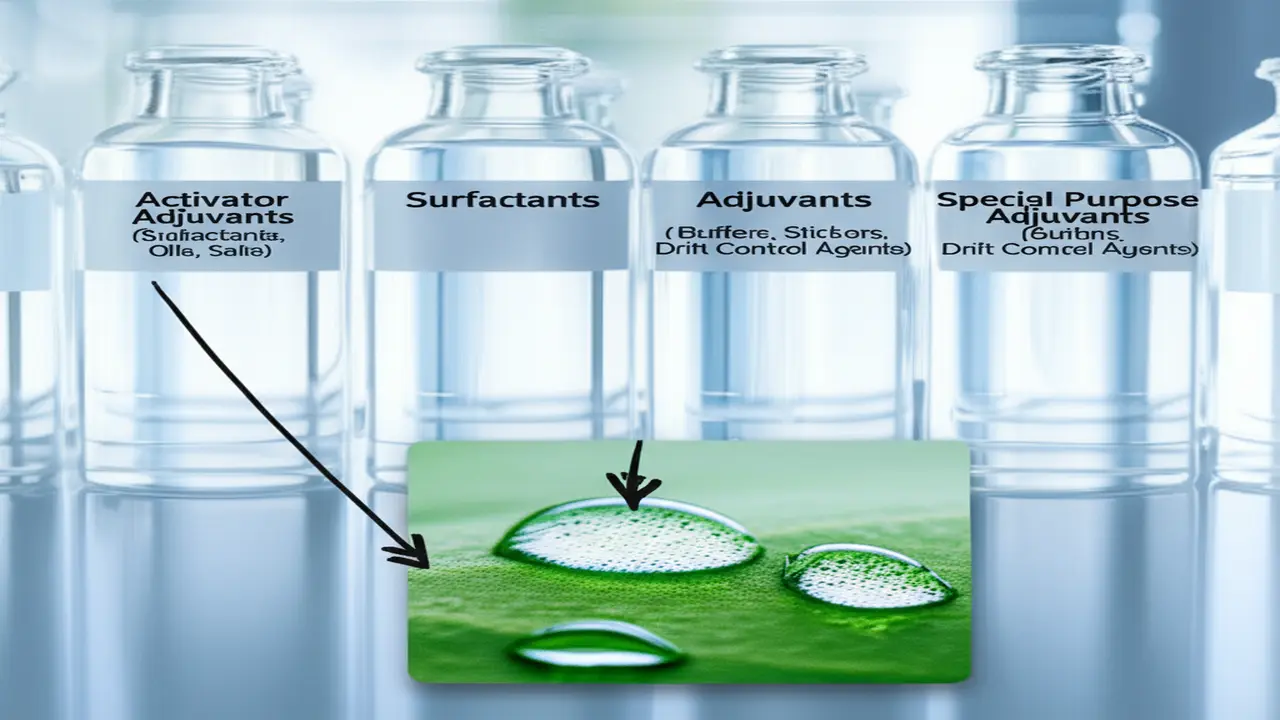

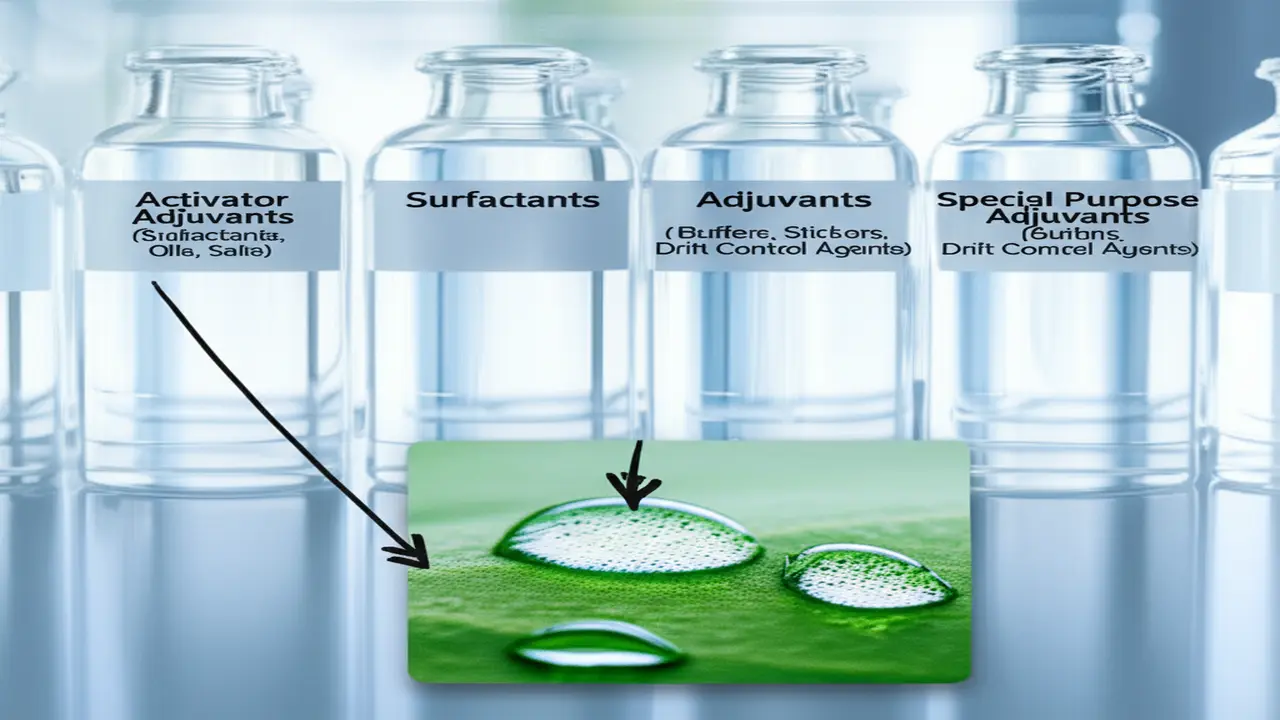

To properly enhance the effectiveness of treatments, it is essential to understand the different adjuvants for pesticides. These additives are broadly sorted into two main categories based on who adds them. First, there are the built-in or formulatory adjuvants, which are already included in the pesticide product by the manufacturer. The second category, and our focus here, consists of spray or tank-mix adjuvants. These are separate products that you, the applicator, add to the spray tank just before use. Making the right choice from the vast market of tank-mix adjuvants in 2025 is critical for optimizing performance. It can mean the difference between a successful application and wasted product, time, and money, directly impacting your results and the health of your plants.

Spray (Tank-Mix) Adjuvants

These are the adjuvants added by the end-user to the spray mixture. They allow for customized solutions tailored to specific environmental conditions, crop types, and pest pressures.

* Surfactants: Their primary function is to reduce the surface tension of water droplets. This allows the pesticide spray to spread more evenly over a leaf’s surface, improving coverage and absorption. They are also known as wetting agents.

* Stickers: These help the pesticide adhere to the plant surface. This is particularly useful in rainy or windy conditions, preventing the product from being washed or blown off the foliage.

* Emulsifiers: These are vital for mixing products that don’t naturally combine, such as oil-based pesticides with water. Emulsifiers ensure the mixture remains stable and evenly distributed in the tank.

* Drift Control Agents: These increase the size of spray droplets to reduce the risk of spray drift, which is the unintended movement of pesticide away from the target area. This is crucial for protecting non-target plants and sensitive environments.

* Antifoaming Agents: Their purpose is to prevent the formation of foam in the spray tank during agitation and mixing. Excessive foam can cause application problems and inaccurate dilutions.

4. Guidelines for Selecting and Using Adjuvants

Selecting the correct adjuvants for pesticides in 2025 is a critical step for maximizing effectiveness and ensuring safety. Making an informed choice prevents wasted product, potential crop damage, and unnecessary environmental impact. Always prioritize a systematic approach to selection and use.

First, the pesticide label is the most important document. It is a legal requirement to follow its directions. The label will specify if an adjuvant is needed and, if so, what type, such as a nonionic surfactant or a methylated seed oil. Ignoring these instructions can render the application ineffective or illegal.

Second, always confirm compatibility. This involves more than just the pesticide and adjuvant. Consider the crop’s sensitivity and the application equipment. For example, an adjuvant that is perfect for a coarse spray on a dormant orchard might be harmful to young vegetable starts. A simple jar test before filling your sprayer can prevent physical incompatibility, which can lead to clogged nozzles and uneven coverage.

Finally, evaluate safety and environmental factors. Some adjuvants can increase the rate of pesticide absorption through skin, requiring extra personal protective equipment. Others may pose a higher risk to non-target organisms like pollinators or aquatic life. Always read the adjuvant’s Safety Data Sheet (SDS) and consider using products with lower environmental footprints when possible.

5. Benefits and Application Scenarios for Adjuvants

In 2025, think of adjuvants as performance boosters for your chemical treatments. The primary benefit is making your pesticides more effective, which saves time, money, and reduces the total amount of chemical applied. Adjuvants for pesticides work by solving common application problems. For instance, surfactants reduce the surface tension of spray droplets, ensuring a thin, even layer on waxy or hairy leaves rather than letting the water bead up and roll off. This is crucial for contact herbicides. Other adjuvants act as stickers, helping the pesticide adhere to the plant through rain or irrigation, while drift control agents create heavier droplets that are less likely to be blown off-target.

You should consider an adjuvant whenever the pesticide label recommends one or when facing specific environmental challenges. If you are spraying on a windy day, dealing with hard water, or treating plants with waxy cuticles like ivy or cabbage, an adjuvant is a smart investment. For example, when using a systemic herbicide on tough perennial weeds, a quality nonionic surfactant ensures the chemical can penetrate the leaf surface for effective uptake. While chemical controls are powerful, they often work best as part of an integrated strategy that also includes mechanical removal of weeds with tools like the best hand cultivators for complete garden care.

6. Specialty Applications: Organic Farming and Beyond

The world of organic farming operates under a fundamentally different philosophy than conventional agriculture, especially concerning crop inputs. While the goal is to minimize external applications, certain approved pesticides are permitted. The role of adjuvants for pesticides in these systems is therefore subject to intense scrutiny. For a product to be used on a certified organic farm in 2025, every single component, including the adjuvant, must be compliant with standards set by bodies like the National Organic Program (NOP) and listed by organizations such as the Organic Materials Review Institute (OMRI). Using a non-compliant surfactant or oil can void a farm’s organic certification, a catastrophic outcome for any grower. Permitted adjuvants are typically derived from natural sources, like yucca extracts, plant-based oils, or specific minerals. They perform the same functions of spreading, sticking, or penetrating, but without the synthetic chemicals banned in organic production. Always verify OMRI listing before adding any adjuvant to your organic spray tank.

7. Frequently Asked Questions (FAQ)

Here are some of the most common questions we receive about adjuvants for pesticides in 2025.

– What is the primary function of an adjuvant?

An adjuvant is an additive used to enhance the effectiveness of a pesticide. It does not have pesticidal properties itself. Instead, it helps the main chemical perform better by improving things like sticking, spreading, or penetration on the target surface. For example, a surfactant is a type of adjuvant that reduces the surface tension of the pesticide spray, allowing droplets to cover more leaf area instead of beading up and rolling off.

– Do I need to add an adjuvant to every pesticide?

Not necessarily. The most critical step is to always read the pesticide label. Many modern pesticides are sold “pre-formulated,” meaning they already include all the necessary adjuvants. For others, the label will specify if an adjuvant is required and may even recommend a particular type, such as a non-ionic surfactant (NIS) or crop oil concentrate (COC), for optimal performance. Using an un-recommended adjuvant can sometimes decrease the pesticide’s effectiveness or even cause harm to your plants.