Garden Fork Troubleshooting: Comprehensive Guide to Repair & Maintenance

Maintaining an efficient garden fork can drastically improve your gardening experience. Proper troubleshooting, timely repairs, and regular maintenance keep this indispensable tool in peak condition, ensuring it performs optimally season after season. This guide offers precise methods to diagnose common issues, undertake safe repairs, and maintain your garden fork effectively, promoting longevity and reliability.

I. Introduction: Revive Your Garden Fork – Why Troubleshooting & Repair Matters

A well-maintained garden fork is essential for tasks such as aerating soil, turning compost, and loosening ground. Neglecting its upkeep can lead to inefficiencies or even injury. Repairing instead of replacing often saves money and lessens environmental impact. This expert guide covers diagnosing faults, executing effective repairs, performing routine maintenance, and knowing when replacement is unavoidable.

II. Essential Preparations: Safety First & Tools You’ll Need

A. Safety Precautions

Start any repair or maintenance work with protective gloves and eye protection to shield against sharp edges and rust particles. Always work on a sturdy workbench equipped with a vise to hold the fork securely. Handle rusty and sharp components cautiously to prevent wounds or infections.

B. General Tools & Materials

To troubleshoot and repair your garden fork, gather the following tools and supplies: hammer, pliers, screwdrivers, and wrenches for mechanical adjustments; cleaning tools like wire brushes, steel wool, and clean rags for surface maintenance; rust removers, such as white vinegar, oxalic acid solutions, or commercial rust removers; lubricants including penetrating oils and linseed oil for wooden handles; adhesives like wood glue or epoxy resin; fastening devices such as wooden wedges and bolts; and sharpening devices such as metal files, whetstones, or grinding stones.

III. Diagnosing Your Garden Fork’s Problem: A Quick Checklist

Begin with a thorough inspection to identify issues:

- Handle: Look for looseness, cracks, dryness, or breaks that can affect grip or stability.

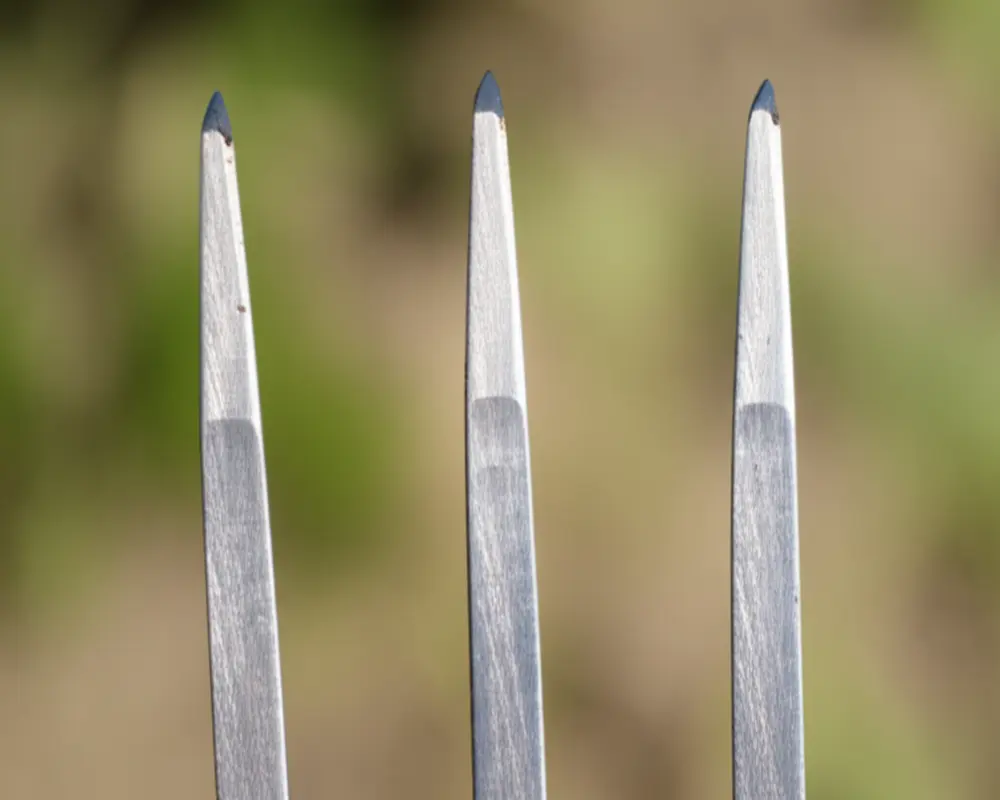

- Tines: Check for bending, breakage, blunting, or severe rust that compromises effectiveness.

- Ferrule/Socket: Examine the metal ferrule for looseness, cracks, or corrosion that weaken the connection.

- General Condition: Evaluate the overall rust extent, surface pitting, wobbliness, or unusual noises during use.

IV. Step-by-Step Solutions for Common Garden Fork Problems

A. Fixing a Loose Handle (The Wobble)

Handle looseness commonly results from wood shrinkage or worn-out wedges. To restore solidity:

Solution 1: Remove the old wedges from the handle socket. Insert new hardwood wedges coated lightly with waterproof wood glue, then tap them in firmly to expand the handle’s grip inside the ferrule. This technique provides durable tightness when done correctly.

Solution 2: For minor looseness, reinforce the handle collar by applying epoxy resin around the joint. Allow full curing to enhance grip stability temporarily.

Solution 3: Severe looseness may necessitate drilling a bolt horizontally through the ferrule and handle to lock the connection mechanically. Use a corrosion-resistant bolt and secure it with nuts on both ends.

However, if the handle shows deep cracks or repeated looseness, it is advisable to replace it altogether.

B. Replacing a Broken Handle (The Snap)

If the handle cracks or breaks beyond repair, replacement is safest and most effective. Begin by detaching the broken handle—often by cutting or hammering it out from the socket. Choose a replacement handle made from durable materials such as ash wood known for shock absorption, fiberglass for strength and low maintenance, or steel for heavy-duty use.

Measure the socket length accurately and select a handle diameter that fits snugly. Insert the new handle, secure it with wedges or bolts, and treat wooden handles with linseed oil to preserve them.

C. Straightening Bent Tines (The Curve)

Bent tines affect soil penetration and load distribution. To realign:

Clamp the fork securely in a vise. Using a mallet or hammer, gently tap the bent tine back into place. Avoid forcing straightening quickly as this can cause metal fatigue and fracture. Evaluate if the tine maintains integrity post-straightening; replacement might be necessary for heavily stressed or broken tines.

D. Sharpening Dull or Blunt Tines (The Struggle)

Sharp tines improve penetration and reduce effort. Use a metal file or grinding stone to restore the points. Consistently maintain the original bevel angle, typically around 30 degrees. Work slowly in one direction and avoid overheating the metal, which can weaken it. Wear gloves and eye protection during filing for safety.

E. Removing Rust & Corrosion (The Orange Bloom)

Rust is inevitable but manageable. For light rust, scrub with a wire brush to remove flakes, then coat the metal with a light machine oil or penetrating oil to prevent further oxidation.

For heavy rust, soak the affected parts in white vinegar or apply commercial rust removers containing oxalic acid. Then sand the surface with steel wool or sandpaper to smooth it out. Always wear gloves and eye protection when handling chemicals, and work in a ventilated area.

F. Addressing a Cracked or Loose Ferrule/Socket (The Instability)

A cracked ferrule impairs tool stability and safety. Temporary fixes include using sturdy metal clamps or applying epoxy putty for minor cracks. These serve as short-term solutions until professional welding is arranged or the fork head is replaced. Structural damage often indicates replacement necessity to ensure safety during use.

V. Repair or Replace? Making the Smart Decision

Deciding between repairing or replacing a garden fork depends on the severity and type of damage:

Repair when: Handles are loose but unbroken, rust is superficial, and damages are minor. These can be fixed through wedging, cleaning, or straightening, extending the tool’s lifespan at low cost.

Replace when: Ferrules are structurally compromised, multiple tines have significant bend or breakage, or rust damage permeates the metal to undermine tool integrity. In such cases, replacement ensures safe, reliable functionality.

VI. Preventative Maintenance: Keeping Your Fork in Peak Condition

Routine upkeep preserves your garden fork’s performance:

- After each use, remove soil and organic debris with a brush or water rinse, then dry immediately.

- Apply light coats of penetrating oil to all metal parts regularly to prevent rust formation.

- Store the fork in a dry, sheltered environment away from moisture exposure.

- Treat wooden handles with boiled linseed oil periodically to maintain flexibility and prevent drying or cracking.

- Conduct routine inspections for signs of wear or damage to address issues early.

- Use the garden fork correctly, avoiding excessive force or misuse that can hasten wear.

For more on general garden spade and tool care, review our detailed recommendations on garden spade maintenance.

VII. Conclusion: A Well-Maintained Tool is a Lifetime Companion

Thorough garden fork troubleshooting, repair, and maintenance practices ensure your tool remains reliable, efficient, and safe. Timely fixes save money and reduce waste, while preventative care extends usability for seasons to come. Use this guide to empower your gardening tasks with resilience and confidence, transforming your garden fork into a lifelong partner for flourishing soil cultivation.

“The best garden tools are those that have been cared for with knowledge and dedication.”

FAQs About Garden Fork Troubleshooting

Q1: How often should I inspect my garden fork for issues?

It is wise to inspect your garden fork before and after each gardening session to catch loose handles, bent tines, or rust early, preventing further damage.

Q2: Can I use household vinegar for rust removal?

Yes, white vinegar is an effective, natural rust remover for light to moderate rust. Soaking tines for several hours then scrubbing with steel wool usually clears surface rust well.

Q3: What type of wood is best for garden fork handles?

Ash wood is preferred due to its strength and shock absorption. Fiberglass and steel handles are alternatives offering durability and reduced maintenance.

Q4: How can I prevent my garden fork from rusting?

Keeping the fork clean, dry, and coated with oils after each use deters rust. Store it in dry conditions and apply linseed oil on wooden handles regularly.

Q5: Is it safe to weld a cracked ferrule myself?

Welding garden fork parts requires skill and equipment and is best left to professionals. Incorrect welding can weaken the tool and pose safety risks.

For additional authoritative tips, consult The Spruce’s guide on garden tool maintenance or detail-oriented instructions on Gardening Know How’s guide to fixing garden forks.